Hose workshop

Home » Products » Hydraulics and pneumatics » Hose workshop

Hose workshop

In addition to our stocked goods, we have our own hose production in Kristiansand and at Skedsmokorset approved by DNV-GL and Bureau Veritas.

On the total of 10 production lines, we can press from 1/4 "to 4" hydraulic hoses. We have three pressure test chambers for testing up to 3655 bar (53011 PSI). We can offer flushing of hydraulic hoses if needed. Contact us at 63 80 58 45 or olje@oo.no to hear more about our hose workshop.

Certifications and documentation

As a certified Parker distributor, Otto Olsen's hose workshop meets the necessary quality standards for hose connections with working pressures of up to 69.0 MPa as well as storage, production and quality control procedures, traceability, documentation and training.

The company's staff trained by Parker are able to manufacture, fit and pressure test hydraulic hoses to the required performance specification. We are approved self-certifiers by DNV-GL and Bureau Veritas and can supply thorough documentation on everything we produce.

We also offer manufactured hoses and pipes that require approval from other class companies, e.g. ABS, LR, Rina, CCS, MarED, VG, BS6853, USCG, KR. An inspection is then carried out with the respective class company and an accompanying survey report.

To hear more about our approvals and documentation, contact Tommy Nilsen at (950) 33 187 or tommy.nilsen@oo.no

Documentation package and MRB

For orders and projects with additional services and documentation requirements, can vi offer our customers the following services including services provided by 3rd parties such as:

- MRB Manufacturing Record Book

- 2.1 CoC sertifikat

– 3.1 Material certificates

– 3.2 or survey report from a class company

– Test certificates such as straits, chemical, flushing etc.

– Material declarations that Asbestos, Reach, Compliant

– Type of approval

– Calibration certificate

- Welding

- bending

– Country of origin certificate

– Digital measurement

– HMS Safety data sheet

Unique identification and tracking system

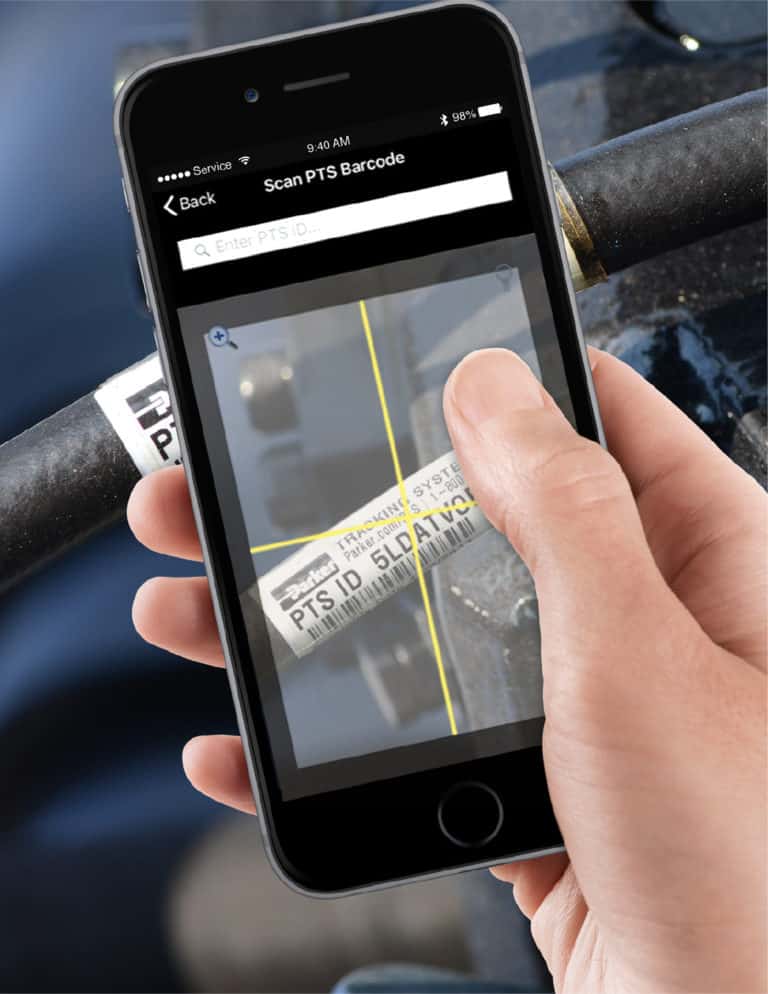

Our Parker hoses are marked according to the Parker Tracker System (PTS) - a tracking system based on a unique identification code for each hose component, which is printed on a solid barcode or RFID label.

This provides fast and accurate product identification that speeds up replacement. The hose component can be replaced with only the PTS ID number, which means that you do not have to remove hoses before they need to be replaced - this can increase the operating time of the machine and enable repairs that are more suitable for you.

To hear more about the Parker Tracking System, contact Tommy Nilsen at (950) 33 187 or tommy.nilsen@oo.no

Do you have any questions?

Send us a message or contact the department directly if you want help finding the solution that is right for you.